Sharpening tools

Sharpening is the most common “repair” needed. Even from new many kitchen knifes, plane irons, chisels need sharpening. With a knife I always suggest if it won’t cut a thin slice off a ripe tomato it isn’t sharp, for a chisel a clean cut across the grain without tearing is wanted.

We do offer a sharpening service for many types of tools excluding saws. Normally we quote a week, but can often do them quicker. Example prices

Plane irons, chisels £4.00 ea

Axes, bill hooks £6.00 ea * some needing a lot of grinding maybe more

Knives, spokeshave irons £4.50 ea

- Knives, spokeshave irons £4.50 ea

- Gouges outside ground £5.00 ea

Gouges inside ground £6.00 ea

Scissors, shears, secateurs £5.00 ea

Long handles shears £7.50 ea

Spoon carving knives (hook knives) £7.00

Its not difficult to sharpen most tools yourself. We often show and explain how to do it in the shop. The last thing you want is late night trying to finish a job and your tools won’t cut properly. That’s not the time to take them to someone else to do the sharpening. Hopefully when I learn more about webpage building will put a tutorial online with our suggestions for sharpening.

Repaired old tools as examples

Tools used to be much more expensive relative to wages then they are now and society had much less of the throw away mentality. People often mended things to keep them going. Sometimes in very elegant ways and yes, sometimes as a real bodge. Hopefully the mending mentality is slowly returning, but often things are now built in ways making it difficult to repair.

Here a Preston reeder shave has had nuts repurposed from something else, maybe re-tapped to bring it back into use. We’ve been know to spend an hour finding a nut or custom making one for something to sell at a pound, silly, certainly not economic, but puts it back to use and saves landfill. Sometimes you might want to save something for sentimental reasons so normal economics don’t come into play. It can also be very rewarding just to see something repaired and used.

A Preston vintage Bull Nose plane could be a joy to use, but it is a bit delicate. It’s cast iron so doesn’t weld but can be brazed. Brazing can distort the casting, so two here have had brass plates bolted or riveted on sometime in the past. One is just mending a crack.

The other the complete front has be remade, bolted and soft soldered in place. This second one also had an adjustable brass fence tapped and bolted to the base. Both end up as usable tools.

An early No 4 Stanley smoothing plane which had a crack in the casting by the mouth and someone riveted a brass plate over it. A repair which keeps the plane usable.

A Rabone Chesterman 33ft leather bound steel tape measure which was in good condition but with a broken tape repaired by using a length of feeler gauge riveted to the backside of the tape. Able to keep the accuracy of the tape and still reels into the case OK. Using 4 small rivets to keep it all aligned and flattened down well.

Preston adjustable mouth metal spokeshave which has old repair to the mouth adjustment mechanism. Even the spring in the moving adjustment has been kept. One handle also cracked and repaired with weld.

Plastic often goes brittle with age and this pair of reasonably inexpensive scissors had a broken handle. I patched it with epoxy and tiny bits of cotton fabric as reinforcing across the breaks. Took about 40 minutes to restore to as usable as new.

Stanley No. 75 is a good useful budget bullnose plane which can have the mouth width changed by sliding the top section. The iron is held in place by a simple lever cap and screw, these can easily become lost or sometimes broken. The plane at the back has the lever cap while someone has replaced it with a simple wooden wedge at the front. Brings it back to being a usable tool.

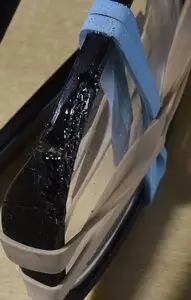

Hammers and other wooden handled tools sometimes end with a cracked handle. Repairs can be done with first glueing the split back together then binding with string ideally soaked in adhesive. This bring the handle back into use and is much stronger than using tape. I’ve done it with epoxy or a ureaformaldehyde, avoiding adhesives which might become sticky if wet. Work adhesive into the crack, smear the surface with it then wrap string or heavy thread around.

Pair of my glasses which I use with the computer just split the plastic frame so the lens could fall out. OK, time to repair them, both cheaper and faster than replacing. A tiny bit of two part epoxy some short lengths of strong thread to bridge the gap opened by the break. Held lens and frame tight with rubber bands.

Gently sanded the frame so both clean and giving a key. Mixed up a tiny amount of two part 5 minute epoxy adhesive. Really only need to squeeze out a few millimetres from each tube, about as small an amount as can mix on a bit of waste plastic. Mix well then dabbing along edge of the frame, drop in thread bits as strengthening and glasses back in use half an hour latter.

Many items can be repaired, refurbished

Garden tools can have new handles put on (which we don’t normally do). Power tools can have cords replaced. Computers can have motherboards replaced, keys replaced on keyboards, iPhones screens replaced, etc. We always advocate that you can learn to do these jobs yourself, but volunteer repair cafes and events have sprung up in many cities either to do the repair or teach how to do it. Learning to repair has no gender or age restrictions it just needs an interest in doing it, sometimes a bit of patience.

Not worth repairing?

This is one is past sensible repair as the shank has actually split lengthwise, but the head is mushroomed over from use. These mushroomed burs can be very sharp, can splinter off as high speed shrapnel when hit and need to be ground off.

Just not worth doing the grinding on this example.

Some things arrive into the shop beyond sensible repair or even sensible cleaning. A Stanley No 4 smoothing plane with a bit too much rust, cracked handle might be able to salvage a few parts from. Another Stanley plane with a broken side, heavy rust on the iron as well as body is an example of one might not even be able to salvage much from. A wooden plough plane with rusted sole plate, wood not in a good state. Sometimes we can salvage parts from otherwise scrap, occasionally pass on to someone teaching apprentices how to restore tools.

Really large repair jobs

When it comes to bigger things like houses almost everything can be done competently by DIY but you may have to do a bit or even a lot of study on the specific topic for some jobs. Start with smaller simpler jobs to gain experience and work up to the more complex. It can be very rewarding. It can save a fortune, but can take time. Here we need to disclose a vested interest, doing DIY, refurbishments, repairs on houses and flats often needs tools.

If you know something about the work and don’t want to or don’t have the time to actually do a job it will at least help in talking to a builder about what is wanted. You are paying a good builder for knowledge, skill and time which may be well worth it.

Early in my start at DIY I needed some gas pipes changed. A British Gas engineer did the job, turn the gas back on, left and I discovered a cut off gas pipe unstopped pouring out gas. I decided that I needed to learn about gas work and did my own for years after. Now the government and trade bodies insist on training, certificates and registration for work on gas systems. Many other trades need certificates for commercial work, it keeps the training bodies well funded, but often you can do the work for yourself even if it needs mandatory checking after.

The competent builder often isn’t allowed to do work without certificates so they and you are also paying for this.